9 Tips to Choose an Ideal Tabletop Dental Autoclave for Your Dental Clinics

When it comes to dental procedures, you may know the infection control has been a crucial part of your clinics’ safety and healthcare standards. And infection control has a tight connection with proper sterilization. Proper sterilization can prevent cross -contamination and disease transformation happened in dental clinics.

As a busy practitioner, autoclaves are not something new to you. After all, you and your staff members count on the autoclave to sterilize dental instruments and surgical tools every day. The right autoclave is vital and an essential piece of equipment investment for your dental clinics

If you are in the market for a new dental autoclave, here are several tips that will help you when making your decision. Thus, you’ll get the most out of your investment and it withstands the test of time.

What Is A Dental Autoclave?

The Dental Autoclave, also called a steam sterilizer, is the machine that utilizes the power of high-temperature reaching 250°F to 270° F and replacement of air by saturated steam to completely sterilize germs on dental instruments and surgical tools. In dental clinics, they are generally low and narrow on space so that front-loading tabletop autoclaves (also called bench-top autoclaves) in compact design perfectly fit in and are a great way to maximize your space.

Safety and Reliability

Reliability is the number one consideration associated with automatic autoclaves. Autoclave used in a healthcare facility is a medical device regulated by the Food and Drug Administration (FDA) and is intended to render medical devices sterile. FDA as a guidance provides recommendations to require that sterile products meet certain sterility requirements before release to the market.

The autoclave chamber is the heart of the automatic autoclave – it works day in, day out to withstand extreme pressure and temperature. If an autoclave chamber is certified by the American Society of Mechanical Engineering (ASME), meeting the standard of Boiler and Pressure Vessel Code (BPVC) section, it guarantees this autoclave chamber built with strict quality control and great safety.

You’ll also need to consider an autoclave with extra safety mechanisms. Automatic autoclaves use high-temperature and high-pressure steam in the defined sterilization time to sterilize instruments and tools. The safety protection mechanism of each autoclave is a crucial consideration. Take door design for example, the automatic double door locking mechanism can be a good choice. It ensures the door is closed during the drying stage and can only open when the sterilization cycle is complete. This feature prevents re-contamination and keeps everyone safe.

Autoclave Automation

In dental clinics, you will commonly see a tabletop autoclave comes in two versions of automatic and manual design. You may have considered a manual autoclave. It’s true that these devices are much less expensive compared to their automated counterparts.

With a manual autoclave, the operator performs various actions. In a word, the operator must control and monitor more process details for the complete sterilization – some critical factors as water filling into the chamber, set the correct temperature and timer, and more.

Conversely, an automatic autoclave performs the entire sterilization cycle with the push of a button. Once you have your sterilization settings ready, the water will flow into the chamber, and then it will automatically start the sterilization.

Without an operator’s input, the autoclave process will not continue running. Here, you need to think about whether your staff has the time to devote to a manual autoclave. An automatic autoclave features pre-programmed every stage of sterilization cycle with easy and quick operation. For busy practices, the automatic autoclaves can improve dental professionals’ work efficiency.

The Volume of Items that Needs to be Sterilized

Ideally, you want an autoclave with a chamber that’s big enough for your largest dental instruments. The volume of items that need to be sterilized every day will determine which chamber size and capacity of your steam sterilizer. The bigger capacity also means more costs and more energy consumption. You can use your largest instruments as a guide in determining your required autoclave chamber size.

Automatic autoclaves come in different shapes and sizes. We often measure the chamber’s capacity in diameters, and the sizes between 9 inches to 11 inches are common on the tabletop autoclave market. Since every autoclave is designed by different inner configurations, it can further determine how many racks fit into the chamber and how you load those items to be sterilized per sterilization cycle.

In a way, the effective sterilization areas can be different even in the same chamber sizes. So you should have a rough idea about how many tools you would sterilize daily. Then you can discuss your needs with your manufacturers or dealers properly. An experienced dealer can recommend the ideal steam sterilizer according to chamber size that can fit your requirement. In general, choosing multiple dental autoclaves with average capacity is better than choosing a larger one as it will save a lot of sterilization time and place accommodation.

Types of Dental Autoclaves

A high-quality automatic autoclave is perfect for sterilizing the following dental instruments at clinics:

- Dental handpieces

- Surgical tools

- Packet of tools

Some materials are not intended for high-pressure steam sterilization and might cause irreversible damage. You must read instructions before you sterilize your tools/instruments/equipment.

There are different kinds of dental autoclaves available in the market. And the most common types are Class N autoclave, Class S autoclave, and Class B autoclave.

As the simplest autoclave, Class N autoclave uses steam to create a downward displacement and then pushes out the air in the chamber before the sterilization cycle begins. However, this method doesn’t ensure complete air removal, especially from hollow or porous instruments, so it can only make instruments with a solid structure sterilized.

Class S autoclave is an intermediate class between N and B, which is suitable for sterilizing wrapped and unwrapped solid instruments that can withstand high pressure and high temperature. If you’re looking for the best choice of dental autoclave, Class B autoclave as the most advanced steam sterilizer has a vacuum pump (pre-and post-vacuum) feature to completely remove air from the chamber. It can sterilize all types of tools.

Class N Autoclave

suitable for unwrapped solid, simple, and raw materials, only for cleaning simple devices

Class S Autoclave

suitable for single wrapped instruments, porous products and small parts. This autoclave integrates performance and functionality, which is a compromising choice on your budget.

Class B Autoclave

suitable for any types of tools and instruments. With fast drying and a powerful vacuum pump, this autoclave features greater flexibility and high-quality sterilization. With the help of the vacuum pump, the complete air removal from the chamber allows better penetration of steam into complex load types to ensure the load can be completely sterilized before use.

Gravity Displacement vs Air Vacuum

In part, autoclaves work by removing air. There are two ways to accomplish this task—gravity displacement and pre-vacuum.

With gravity displacement, the autoclave requires more exposure time typically because the air is evacuated from the chamber in a passive manner. The steam displaces the air in the chamber, and the heavier air was displaced and removed by the force of steam gravity to exit the chamber via the sterilizer drain. Conversely, a pre-vacuum autoclave uses a vacuum pump to remove all the air. Once the autoclave removes all air, it pumps in the steam.

A gravity displacement autoclave is the most basic kind of sanitization equipment. It’s also the most affordable kind of autoclave. It works well for cleaning nonporous items.

However, it’s not always easy to remove air from some dental equipment. In these cases, effective sanitization requires deeper steam penetration. Here, a pre-vacuum autoclave is a better choice.

Types of Loads and Sterilization Cycle Time

The autoclave that you select should have the capability to clean both wrapped and unwrapped instruments. This capability will make the sterilization process easier for your staff. For different type of loads that you’ll need to sterilize, it’s crucial to select the autoclave that has cycles capable of sterilizing your specific loads.

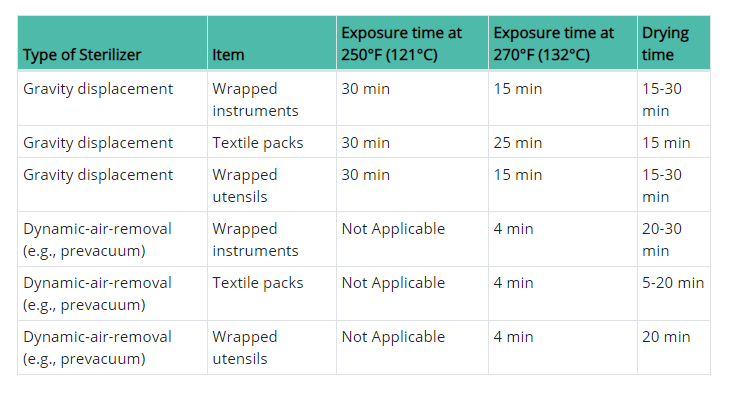

Different types of autoclaves deliver different sterilization time. There are three types of steam sterilization cycles recognized by the Association for the Advancement of Medical Instrumentation (AAMI). The minimum cycle times of dental sterilizer varies depending on temperature, different types of sterile instruments (wrapped or unwrapped), and manufacturer’s instructions. Some of the steam sterilizers are “intelligent” enough to shorter cycle times or reducing the number of sterilization cycles by certain manual activities.

Minimum cycle times for steam sterilization cycles

Autoclaves use steam and are either gravity displacement or pre-vacuum type autoclave. For specific load applications, AAMI have clearly defined the minimum steam sterilization cycles. And each of cycle time performed can be varied by different sterilizer manufacturers. The Class B sterilizer utilizes a powerful vacuum pump and unique technology to reduce overall cycle time and better sterilization performance.

With a smooth user experience, some essential pre-programmed sterilization cycles have been integrated on the intuitive display to easily and quickly select the settings during their busy practices.

| Type of autoclave | Type of Loads | Sterilization Cycle |

| Class N (gravity displacement) | Unwrapped solid instruments or tools for immediate use | Longer sterilization time, longer drying time required |

| Class S (vacuum-included) | Single unwrapped and wrapped instruments, porous products and small parts | Shorter cycle time in some models Pre-programmed sterilization cycle selection |

| Class B (pre-/post-vacuum) | Unwrapped and wrapped instruments/tools, especially for porous loads and hollow instruments for deep sterilization | Shorter total cycle time, provide better penetration and sterilization effect |

Sterilization Record

According to the Centers for Disease Control and Prevention (CDC) and the American Dental Association (ADA), all practicing dentists, dental auxiliaries, and dental laboratories shall follow appropriate infection control procedures described in the 2003 CDC Guidelines. As part of the sterilization process monitoring, you should restore and observe every sterilization record.

Those parameters involve pressure, temperature, and cycle duration that have reached the levels recommended by the sterilizer manufacturers. As a result, the data logging systems have been specifically designed for automatic sterilizers that provide reporting tools for easy analysis and record tracking. Those come in different reporting tools, such as mobile APP, printers, flashcards, or USB drive support.

Ease-of-Use

Having a busy practice every day, you will want to spend less time to use an autoclave with easy-to-use controls to manage the sanitization process. Thus, a unit that comes with pre-programmed sterilization cycles, intuitive and clear navigation with a quick click can be a good choice. What you need is a medical device that can make your workflow more effective and safe within daily limited and hustle hours.

Long-term Benefit for Your Investment

Buying an autoclave is quite an expensive investment, so make sure the unit you choose comes with a few years’ warranties and trained technicians to work on regular servicing, calibration, and maintenance when you need them. If you operate the autoclave relatively more often than other dental clinics, you can check with reputable manufacturers or suppliers to schedule an inspection/maintenance after every 300 cycles.

Since you are likely to use the components of this equipment for the long term, it is best to see the conditions and limitations during the warranty period. Most manufacturers offer one year limited warranty, but some can offer a two- year limited warranty for better reliability.

Again, an autoclave is a considerable investment. It would be better to do your research to ensure you know about the product and your needs.

To get the most out of your autoclave, you should maintain your autoclave well so that it continues to work properly. By doing so, you’ll make sure that it remains suitable for long-term use.

More about AG Neovo Healthcare Automatic Tabletop Autoclave

LouieP Séries

Tabletop Autoclave P-M10TR

Volume 6.3Gal (24 liters) | 3 Trays